VG-10 is the most popular kitchen steel

When selecting a kitchen knife, the steel used in the blade is a crucial factor to consider. VG-10, a type of stainless steel, has gained popularity among chefs and home cooks for its high quality and durability. Developed in Japan by Takefu Special Steel Co. Ltd. in the 1980s, VG-10 quickly became known for its ability to hold a sharp edge and resist corrosion, making it an ideal choice for frequently used kitchen knives.

History of VG-10 steel

VG-10 steel was developed in response to the need for a high-performance stainless steel that could meet the demands of professional chefs and knife enthusiasts…

Takefu Special Steel Co. Ltd. set out to create a steel with excellent edge retention, corrosion resistance, and toughness. VG-10 contains carbon, chromium, cobalt, vanadium, and molybdenum, which provide hardness, edge retention, corrosion resistance, strength, toughness, and wear resistance.

The “VG” in VG-10 stands for “V Gold,” which reflects the high expectations that the manufacturer had for this steel.

Composition – A high-carbon stainless steel

VG-10 is a high-quality stainless steel made up of key elements, including carbon, chromium, molybdenum, vanadium, and cobalt.

Its high carbon content (around 1% to 1.2%) gives VG-10 exceptional hardness and edge retention, making it ideal for high-end kitchen knives.

Chromium (around 15%) enhances its overall corrosion resistance, forming a protective layer of chromium oxide on the surface of the steel to prevent rust and corrosion.

Molybdenum contributes to resistance to pitting and crevice corrosion, while vanadium improves wear resistance and the ability to hold a sharp edge for extended periods.

Cobalt (around 1.5%) improves strength and toughness, critical factors in the performance of high-end kitchen knives.

VG-10 is widely used by well-known knife manufacturers, including Shun, Sakai Takayuki, and Spyderco, and is easy to sharpen and maintain. Its superior stability and robustness make it a top choice for both professional chefs and home cooks. Variants such as VG-10 Damascus steel or Full VG-10 steel offer unique aesthetic and functional features.

Main features of VG-10 steel: A high-performance knife metal

VG-10 steel is a top-quality stainless steel that has become a popular choice for high-end Japanese kitchen knives and other cutlery because of its exceptional performance, durability, and resistance to corrosion and wear.

Hardness and Edge Retention

One of the standout features of VG-10 steel is its exceptional hardness, which allows for the production of sharp, precise edges on knives. The high levels of carbon and vanadium in the steel contribute to its overall strength and durability, making it well-suited for heavy use.

VG-10 steel is also known for its great edge retention, meaning that it can hold a sharp edge for longer periods of time than many other types of knife steel. This is due to the fine, even grain structure of the steel, which helps maintain the sharpness of the edge.

Corrosion Resistance

VG-10 steel’s high levels of chromium make it highly resistant to corrosion. This forms a protective layer on the surface of the metal, preventing rust and other forms of corrosion.

Vanadium Content

VG-10 steel’s high level of vanadium content is another key factor that sets it apart from other types of knife steel. Vanadium is a hard, wear-resistant metal that helps improve the strength and durability of the steel. It also contributes to the steel’s ability to hold a sharp edge over long periods of time.

Versatility

VG-10 steel is a highly versatile material that can be used in a wide variety of applications, such as high-end kitchen knives, hunting knives, and tactical knives. Its exceptional performance and durability make it a popular steel among knife enthusiasts and professional chefs alike.

VG-10 Damascus steel or Full VG-10 steel

VG-10 Damascus steel, also referred to as full VG-10 steel, is a gold standard choice for knife blades due to its unique appearance and impressive performance. The Damascus pattern seen on VG-10 blades is achieved through a process called layering, where sheets of steel are folded and welded together multiple times. This results in a distinctive and aesthetically pleasing pattern on the blade’s surface.

In addition to its striking appearance, VG-10 Damascus steel boasts several desirable properties. The Japanese steel is composed of high levels of carbon, chromium, and vanadium, which contribute to its impressive hardness, corrosion resistance, and edge retention. VG-10 is also known for its ability to maintain a sharp edge over extended periods of use, making it a preferred choice for many professional chefs and knife enthusiasts.

While VG-10 Damascus steel is highly regarded, it is important to note that not all VG-10 steel is Damascus steel. Full VG-10 steel refers to a blade made entirely of VG-10 steel, without the added layering process to create the Damascus pattern. While full VG-10 steel blades lack the distinctive appearance of Damascus steel, they still possess the high level of performance and resilience that VG-10 is known for.

When choosing between VG-10 Damascus steel and full VG-10 steel, it ultimately comes down to personal preference and intended use. Those looking for a knife with a unique and eye-catching appearance may prefer VG-10 Damascus steel, while those prioritizing performance and durability may opt for full VG-10 steel.

VG-10 vs softer stainless steels

Compared to softer stainless steels like 440C and AUS-8, VG-10 steel stands out for its exceptional hardness, toughness, and durability. VG-10 steel has a higher carbon content, making it harder and more wear-resistant, as well as a higher chromium content, making it more resistant to corrosion.

While softer stainless steels are easier to sharpen and maintain, they are not as durable and wear-resistant as VG-10. VG-10 steel can hold a sharp edge for a longer period of time, making it ideal for knives and other cutting tools.

One popular softer stainless steel is 440C stainless steel. While it is a good steel for knife blades, it can’t match the hardness and wear resistance of VG-10 steel. VG-10 steel has a Rockwell hardness rating of around 60-61 HRC, which is significantly higher than 440C’s rating of around 58-59 HRC.

However, VG-10 steel can be more difficult to sharpen than softer stainless steels because of its high hardness. It requires a more refined sharpening technique and a higher level of skill to achieve a razor-sharp edge.

Overall, VG-10 steel is an excellent choice for high-performance knives and cutting tools, especially for those who prioritize edge retention and durability over ease of maintenance. If you’re looking for a steel that can withstand heavy use and maintain a sharp edge for a long time, VG-10 steel is definitely worth considering.

FAQ

Is VG10 considered premium?

Yes, VG-10 is a premium steel due to its high-quality composition. It contains carbon, chromium, cobalt, and vanadium, which give it excellent edge retention, corrosion resistance, and toughness. These properties make it a perfect choice for high-end cutting tools.

Is VG10 easy to sharpen?

VG-10 is relatively easy to sharpen thanks to its fine grain structure, which allows for a keen edge. However, its high hardness level may require more effort to sharpen. Using appropriate sharpening tools and techniques is important to achieve the best results.

Does VG10 hold an edge well?

Yes, VG-10 is known for its ability to hold an edge well. Its excellent edge retention means that it can maintain a sharp edge for longer periods than many other steels. That’s why it’s a popular choice for high-end knives and other cutting tools.

What is VG10 steel good for?

VG-10 is suitable for a variety of applications, including knives, scissors, and other cutting tools. Its high-quality composition also makes it a popular choice for high-end watches and other precision instruments. Its excellent edge retention, corrosion resistance, and toughness make it a top choice for many knife enthusiasts.

Are there no better steels than VG10 ?

While there are other high-quality steels available, VG-10 is widely regarded as one of the best choices for premium knives and cutting tools. Its combination of excellent properties makes it a top choice for many knife enthusiasts. However, the best steel for a particular application may vary depending on the specific needs and preferences of the user.

Can I put VG10 knives in the dishwasher?

While it has excellent corrosion and rust resistance, putting any high-quality VG-10 knife in the dishwasher is not recommended. To maintain the longevity and performance of your VG10 knives (and most other high-quality knives), it is best to hand-wash them with mild soap and warm water. Dry them immediately after washing to prevent any chance of rusting and to preserve the handle’s condition.

Where to buy genuine VG-10 knives?

Here are a few options in stock on our online store…

-

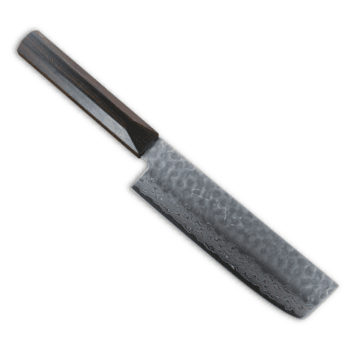

33-Layer Nakiri Wa$222.61

33-Layer Nakiri Wa$222.61 -

17-Layer Santoku Green$210.84

17-Layer Santoku Green$210.84 -

33-Layer Sujihiki Kokushin$305.06

33-Layer Sujihiki Kokushin$305.06 -

Sairyu Western Usuba Navy$140.16

Sairyu Western Usuba Navy$140.16 -

Non Ebony Usuba$346.29

Non Ebony Usuba$346.29 -

33-Layer Petty Wa$151.94

33-Layer Petty Wa$151.94